Überwachung von Laserprozessen in der Produktion

Einfache Lösungen. Standards setzen.

Überwachung von Laserprozessen

in der Produktion

Einfache Lösungen. Standards setzen.

Unsere Produkte

Prozessüberwachung. Datenvisualisierung. Nachverfolgbarkeit.

Unsere Produkte

Prozessüberwachung. Datenvisualisierung. Nachverfolgbarkeit.

Die vollautomatische Prozessüberwachung liefert zuverlässige Produktionsdaten. Über unsere Onboard-Lösungen für die Statistik hinaus liefern wir Lösungen für Data Mining mehrerer Maschinen und vorkonditionierter Daten zur langfristigen Speicherung und Rückverfolgbarkeit auf Ihren IT-Systemen.

Mit einfachen Lösungen gemeinsam Maßstäbe setzen.

Das ist unsere Vision für die Prozessüberwachung in

einer zunehmend komplexeren Produktionswelt.

Unsere Dienstleistungen

Beratung. Inbetriebnahme. Schulung. Weltweiter Support.

Prozessüberwachungsglück

Einfach. Transparent. Glücklich.

Ihr Partner für Laserprozessüberwachung

Mehr als 25 Jahre Erfahrung in der Lasertechnik

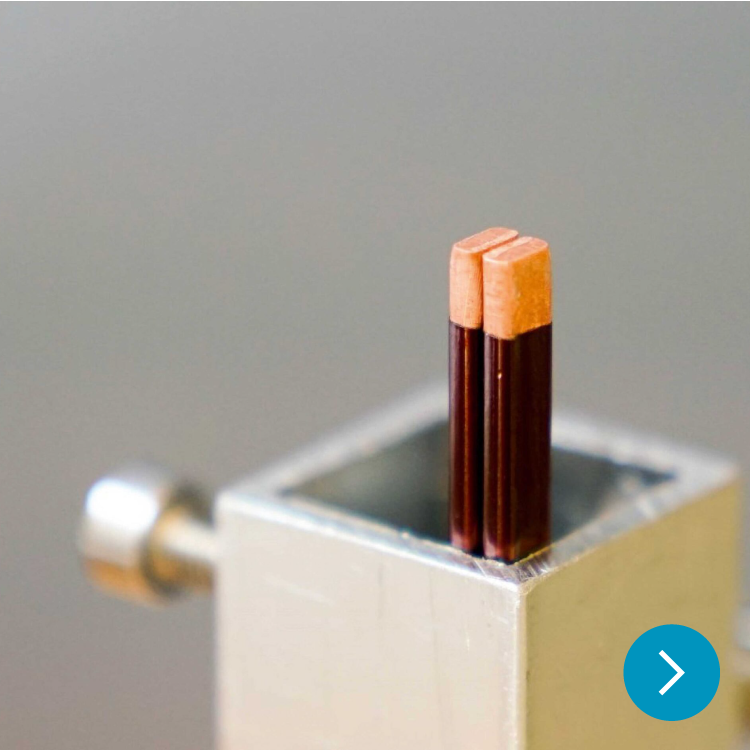

Prozessüberwachung

als Teil der Qualitätssicherung.

Das ist unser Anspruch.

Auf Augenhöhe. Mit Respekt. Transparent.

Stimmen von Kunden und Partnern

Dann schreiben Sie uns eine Nachricht an info@4d-photonics.com.

Kontaktieren Sie uns!

Kontaktieren Sie uns!

Wenn Sie mehr über unsere Produkte und Dienstleistungen erfahren möchten oder ein individuelles Angebot anfordern möchten, kontaktieren Sie uns gerne. Sie können uns telefonisch, per E‑Mail oder über unser Kontaktformular erreichen. Wir freuen uns auf Ihre Anfrage!